Traceable machine vision systems for digital industrial applications (DI-Vision)

Projects

Traceable machine vision systems for digital industrial applications (DI-Vision)

Machine vision systems are crucial to many high-value industries, where Europe is globally competitive, and to the EU objectives for digital transformation and the Green Deal. However, further work is needed to develop:

- To achieve the traceability of existing and future MVSs in combination with other measuring equipment;

- Develop digital twins of MVSs based on data and physically driven models;

- Implement robust matching and analysis algorithms for large amounts of stored raw data.

The tools developed in this project, combined with uncertainty evaluation methods, will be applied throughout industrial applications on macro‑ and microscale specimens in order to reach better accuracy, productivity and flexibility as well as improved safety and cost efficiency.

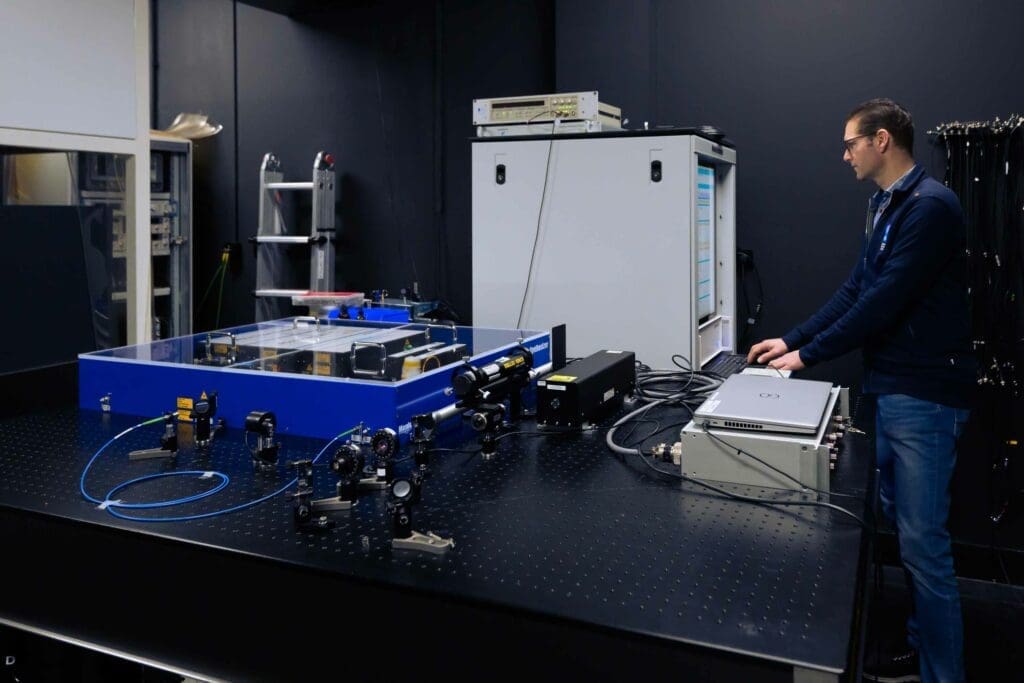

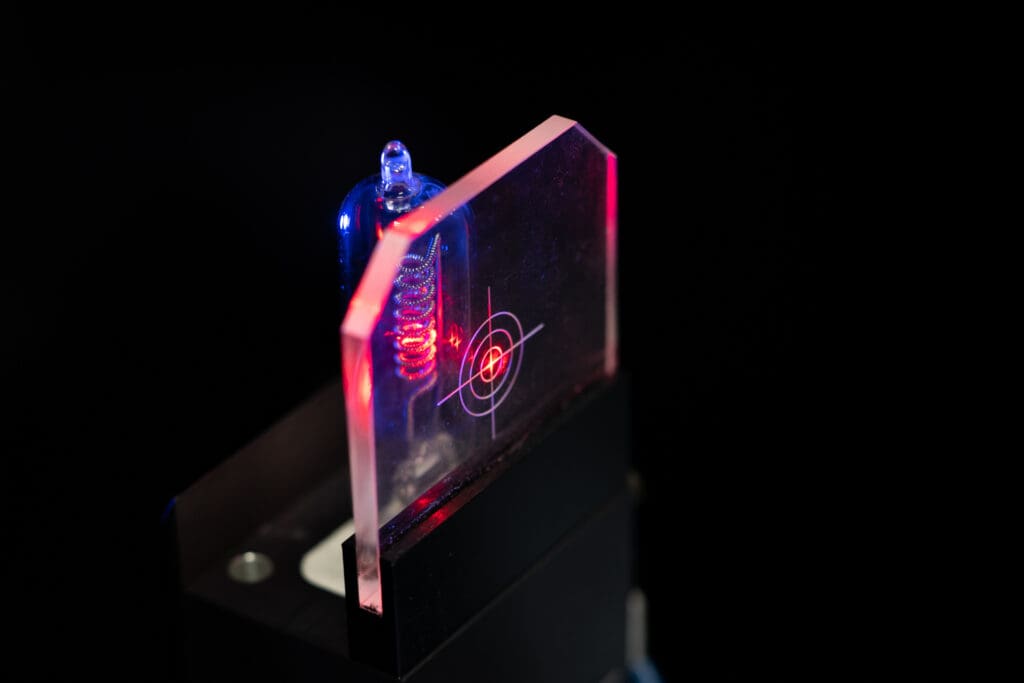

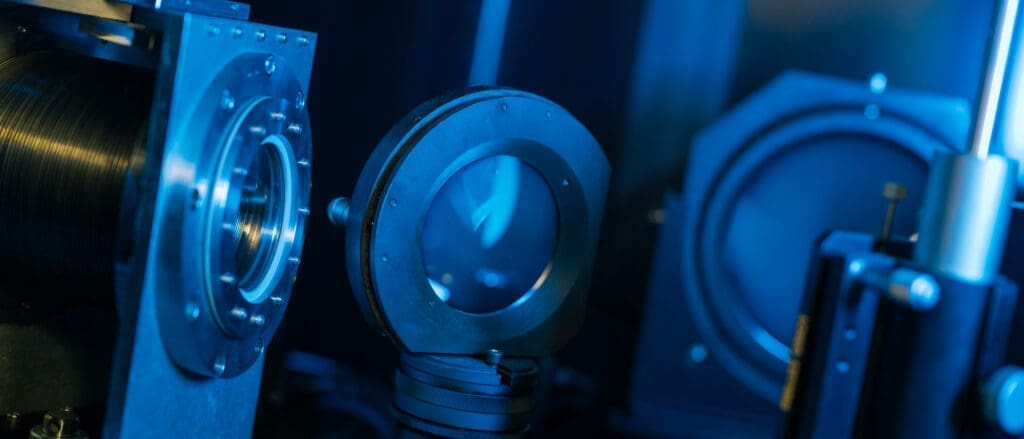

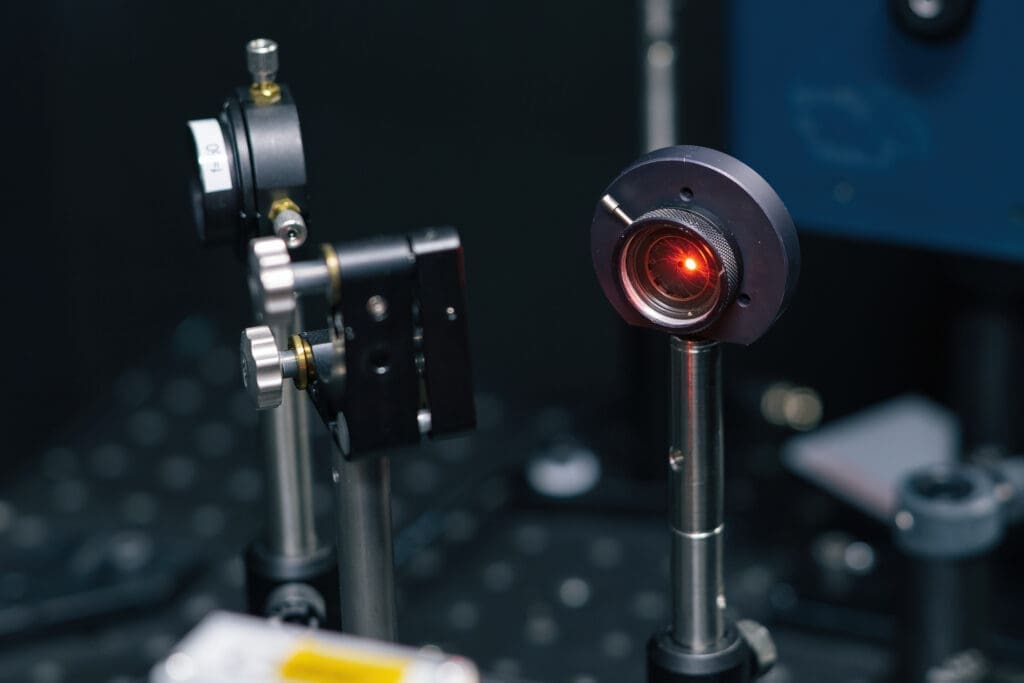

Our role

VSL focuses on two types of machine vision solutions for respectively (1) expansion with an optical high-resolution camera on the 3D-CMM and (2) the optical camera on an HF wafer probing station for advanced control and contact detection. The optical camera on the 3D CMM will be developed for calibrations of 2D grid plates and optical reference standards for microscopes. VSL focuses on developing algorithms for image processing, ensuring traceability and drawing up uncertainty budgets. This is supported by the field of Data Science and Modeling. New methods are also being developed that can serve as a basis for adjustments to existing standards for vision systems on coordinate measuring systems. The machine vision for HF wafer probing will be developed for automated checking and determining the quality of the electrical contact based on the print left behind. The VSL probing system is used to collect a data set of plan view images from probe-substrate contact prints. Ground Signal Ground (GSG) probes, with pitch distances of 150 µm, 100 µm, and 50 µm, are used in combination with gold and aluminum substrates. These substrates are then supplied for characterization of the probe footprint by an external partner, in combination with which the dataset of top view images is used to develop algorithms.

Startdatum: September 1, 2024 Einddatum: Augustus 31, 2027

More information on the research project can be found on its web page https://projects.lne.eu/jrp-di-vision/

“The project has received funding from the European Partnership on Metrology, co-financed from the European Union’s Horizon Europe Research and Innovation Programme and by the Participating States.”

Would you like to know more about this subject?

Our experts are happy to help. Walter Knulst Principal Scientist Length & Optics

Projects

Our expertise in practice

Read more about our projects.