Sensor engineering for vibration isolation in Einstein Telescope (SENVIDET)

Projects

Sensor engineering for vibration isolation in Einstein Telescope (SENVIDET)

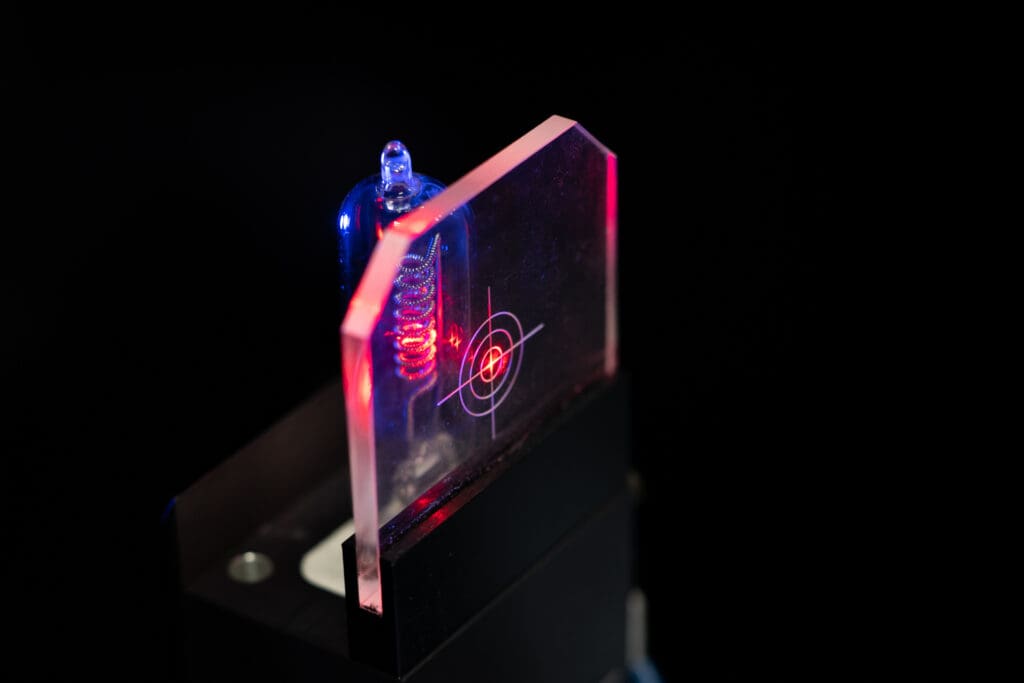

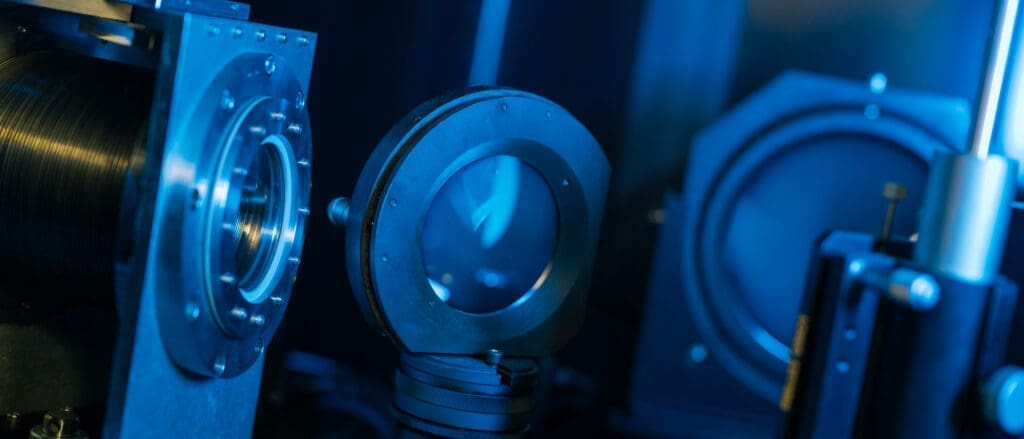

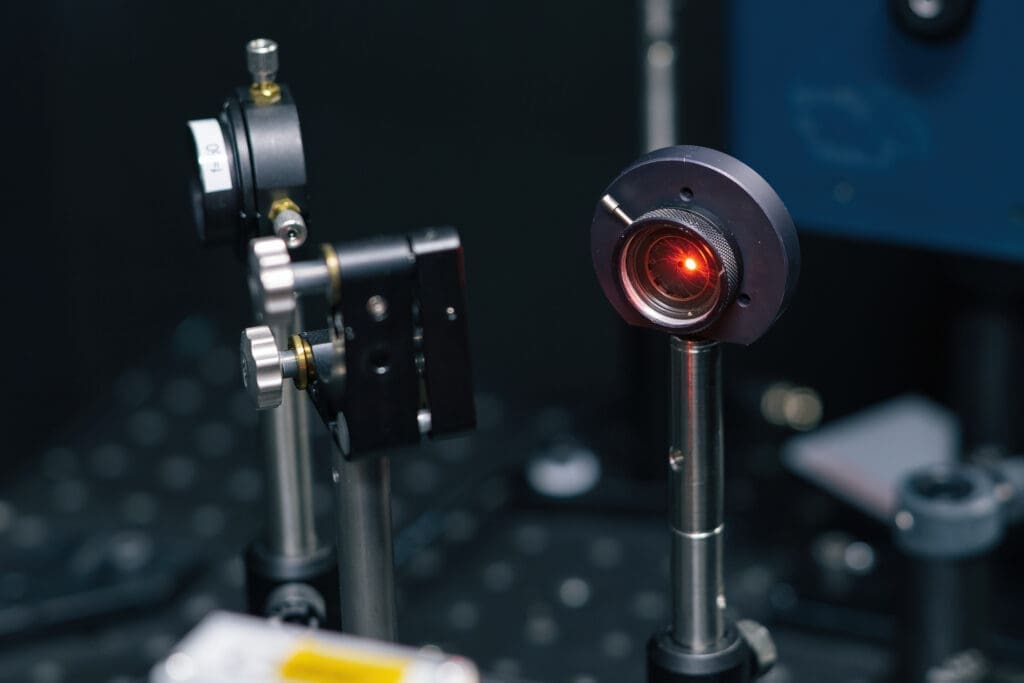

Project SENVIDET contributes to the development of the Einstein Telescope through innovation in the field of sensors for vibration isolation. The challenges addressed here relate to seismic signal disturbance due to tilting of the gravitational wave telescope optics and requirements for precise and accurate relative distance measurement. A plan is proposed by four SME participants, two knowledge institutions and a high-tech system integrator for the development of a new generation of inertial rotation sensors and interferometric distance sensors, which can provide a solution to the challenges mentioned. Implementation of this plan offers an opportunity for the business community to provide input to the development of Einstein Telescope and at the same time it is an opportunity for valorization by transferring Nikhef’s knowledge to high-tech companies.

Our role

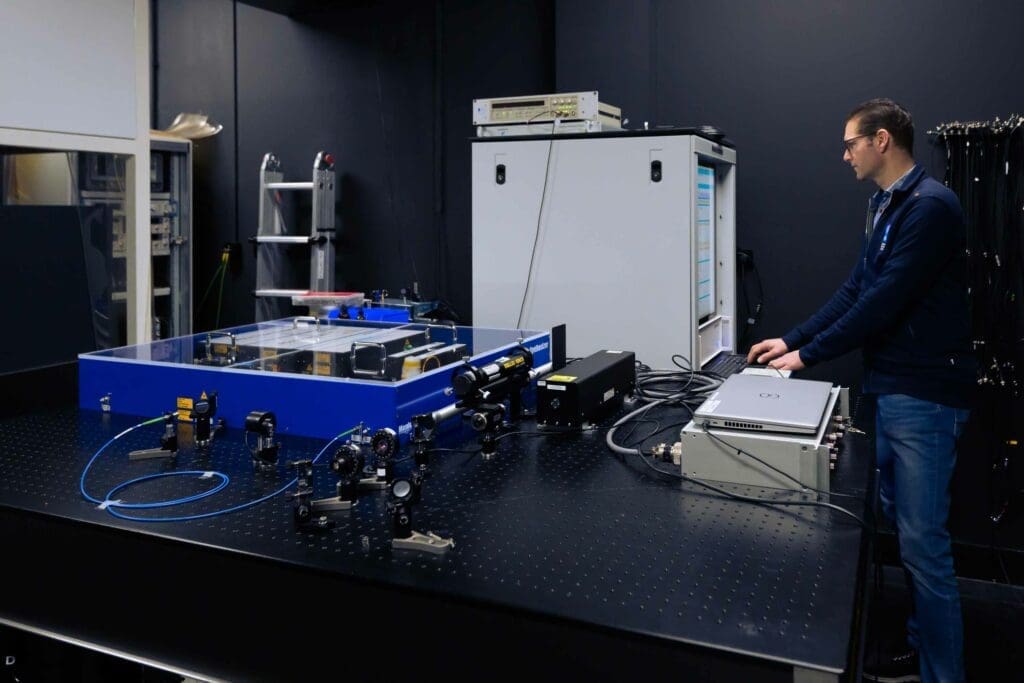

The most important task for VSL within the project is to support and make available our experience and facilities in the field of accurate displacement and vibration measurements. The various sensors developed by the partners in the project will ultimately all be tested at system level using, among other things, VSL setups. In addition, VSL also contributes to drawing up the specifications and technical requirements of some sensors. The various optical sensors that will be developed within the project are divided into (fiber) optical inertial sensors and interferometric sensors. Ultimately, all validation measurements and findings will be reported in a final report at system level together with other partners.

Startdatum: July 1, 2024

Einddatum: June 30, 2027

More information on the research project can be found on its web page www.einsteintelescope-emr.eu

“The project receives funding from the Einstein Telescope technology domain R&D scheme.”

Would you like to know more about this subject?

Our experts are happy to help.

Walter Knulst

Principal Scientist Length & Optics

Projects

Our expertise in practice

Read more about our projects.